1-800-868-2450

My Account | Cart | Checkout

Top 10 Industrial Air Solutions to Optimize Your Facility's Efficiency

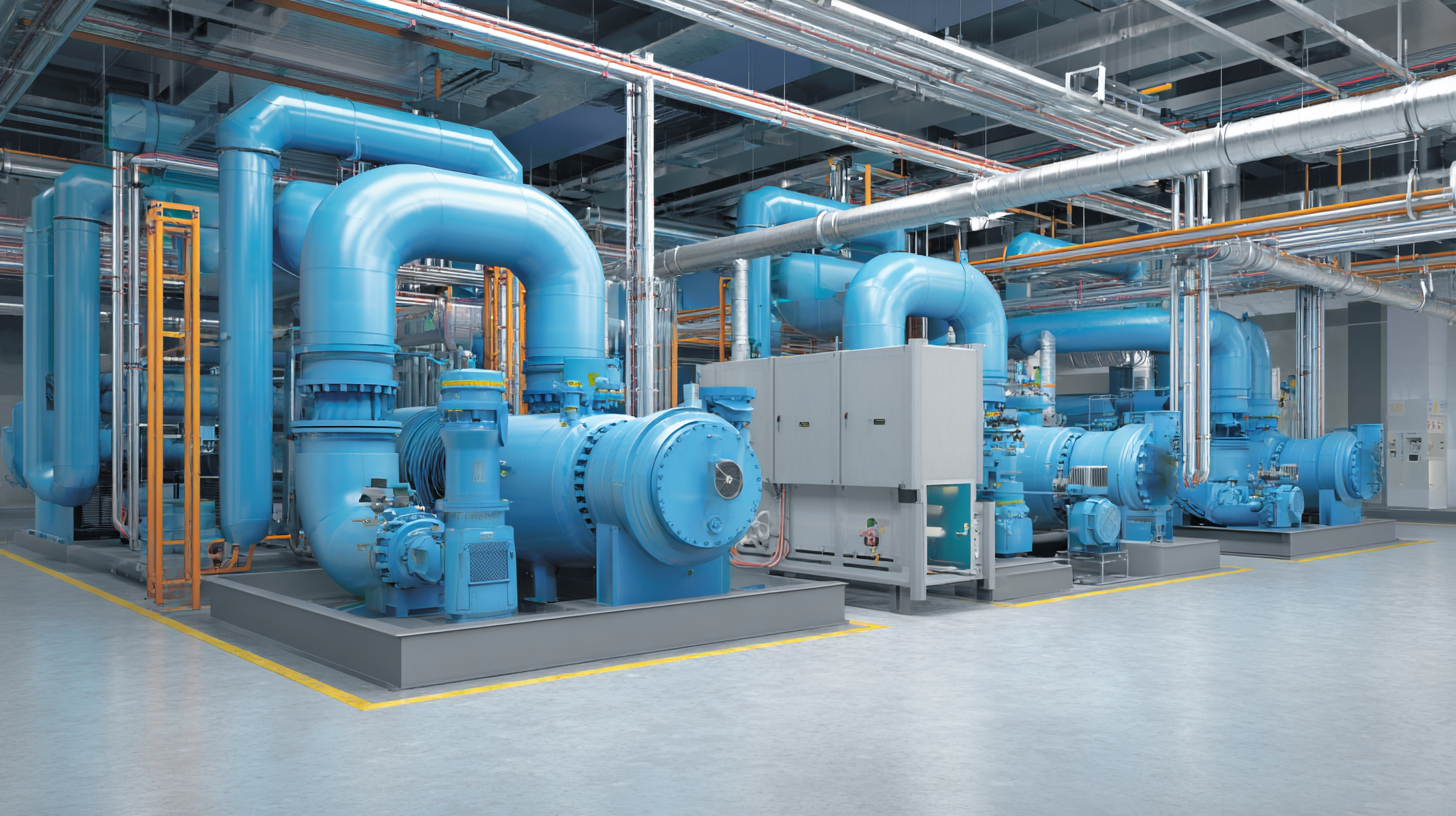

In the ever-evolving landscape of manufacturing and industrial operations, optimizing efficiency is paramount. According to renowned industrial air expert Dr. Emily Carter, "Harnessing the power of industrial air solutions is essential for enhancing workflow and reducing operational costs." As facilities strive to increase productivity while minimizing energy consumption, understanding and implementing the right air solutions can lead to significant improvements in operational efficiency.

As we approach 2025, it becomes increasingly important for facility managers and stakeholders to stay informed about the latest trends and innovations in industrial air systems. Striking the right balance between performance, cost, and sustainability not only ensures a competitive edge but also supports broader environmental goals. This article outlines the top 10 industrial air solutions that can revolutionize your facility's operations, highlighting key innovations and practical strategies for implementation, ultimately paving the way for future success in an industrial setting.

Benefits of Implementing Energy-Efficient Air Compressors in Industrial Settings

Implementing energy-efficient air compressors in industrial settings presents significant benefits that extend beyond mere operational cost savings. According to a report by the U.S. Department of Energy, industrial compressed air systems can account for nearly 30% of total energy usage in facilities. By upgrading to energy-efficient compressors, companies can reduce their energy consumption by as much as 50%, directly impacting their bottom line while also contributing to sustainability goals.

Moreover, energy-efficient compressors often feature advanced technologies such as variable speed drives and heat recovery systems, which optimize air production and minimize energy waste. A study published by the Compressed Air and Gas Institute revealed that companies implementing these systems could reduce greenhouse gas emissions by up to 1.4 million tons annually, equivalent to removing over 300,000 cars from the road. This not only enhances a company’s environmental responsibility but also aligns with the growing regulatory pressures aimed at reducing industrial emissions.

Investing in energy-efficient air compressors also leads to improved reliability and lower maintenance costs. Reports indicate that facilities utilizing modern compressors experience up to a 30% reduction in maintenance expenses, as these systems are designed for longer lifespan and higher efficiency. Overall, the shift towards energy-efficient air compressors is a strategic move for industries looking to optimize their operations and promote sustainable practices.

Advancements in Air Filtration Technology to Enhance Workplace Air Quality

The importance of air quality in industrial facilities cannot be overstated, as it directly impacts both employee health and operational efficiency. Recent advancements in air filtration technology have opened up new avenues for optimizing workplace environments. Modern air filtration systems now employ HEPA filters that capture a higher percentage of airborne particles, including allergens and contaminants that were previously difficult to filter out. By integrating these advanced systems, facilities can significantly reduce the risk of respiratory issues among employees, ultimately leading to fewer sick days and improved productivity.

In addition to HEPA filters, innovative technologies such as electrostatic precipitators and UV-C light air purifiers are enhancing workplace air quality even further. These systems not only capture particles but also neutralize harmful microorganisms, ensuring a cleaner and safer environment. Furthermore, the implementation of smart sensors allows for real-time monitoring of air quality, enabling facility managers to respond proactively to any changes. With these advancements, industries can create healthier workplaces while also potentially lowering their energy costs through more efficient air management systems.

Data-Driven Insights: How IoT Solutions Improve Operational Efficiency in Air Systems

In the age of smart technology, the integration of IoT solutions in industrial air systems plays a pivotal role in enhancing operational efficiency. By leveraging real-time data from interconnected devices, facility managers can monitor air quality, energy consumption, and equipment performance more effectively. This data-driven approach helps identify inefficiencies and enables proactive maintenance, reducing system downtime and lowering operational costs.

For instance, sensors can track fluctuations in air pressure and temperature, providing immediate feedback that allows for adjustments to optimize performance. Predictive analytics can forecast potential issues before they arise, ensuring that repairs are made promptly. Moreover, the ability to visualize data trends through dashboards empowers decision-makers to implement strategies that enhance both productivity and sustainability.

Overall, IoT solutions transform industrial air systems from reactive to proactive models, driving significant improvements in facility efficiency.

Comparative Analysis of Variable Speed Drives vs. Fixed Speed Drives in Air Solutions

When optimizing industrial air solutions, understanding the differences between variable speed drives (VSDs) and fixed speed drives (FSDs) is crucial. VSDs allow for adjustable motor speeds, enabling systems to match airflow requirements more precisely. This flexibility not only enhances energy efficiency by reducing wasted power during lower demand periods but also extends the lifespan of machinery due to less mechanical stress. By seamlessly adapting to varying operational conditions, VSDs contribute significantly to reducing overall energy costs.

In contrast, fixed speed drives operate at a constant output, which can lead to inefficiencies, especially in applications where air demand fluctuates. While initial costs may be lower for FSDs, the operational expenses can accumulate quickly over time due to higher energy consumption and maintenance requirements. Selecting VSDs over FSDs can therefore provide a more sustainable solution in the long run, offering industrial facilities an opportunity to optimize performance while minimizing their environmental impact. The decision should ultimately consider both upfront investments and ongoing energy costs, making a strong case for the implementation of variable speed drives in modern air solutions.

The Role of Predictive Maintenance in Maximizing Air System Performance and Reducing Downtime

Predictive maintenance plays a crucial role in enhancing the performance of industrial air systems, ensuring that they operate at optimal efficiency. By utilizing advanced data analytics and IoT technology, predictive maintenance allows facilities to monitor equipment health in real-time. This proactive approach enables operators to identify potential issues before they escalate into significant failures, thereby reducing unplanned downtime and costly repairs.

In addition to minimizing downtime, predictive maintenance helps in optimizing the overall air system efficiency. It allows for timely replacements and servicing of components, ensuring that all parts function harmoniously. Regular monitoring and analysis of air system performance data also mean that energy consumption can be better managed, contributing to lower operational costs. This strategic focus not only boosts productivity but also prolongs the lifespan of equipment, making predictive maintenance an indispensable strategy for modern industrial facilities aiming for both efficiency and sustainability.

Top 10 Industrial Air Solutions to Optimize Your Facility's Efficiency

| Solution | Efficiency Improvement (%) | Downtime Reduction (%) | Cost Savings ($) | Implementation Time (Weeks) |

|---|---|---|---|---|

| Smart Compressed Air System | 20% | 30% | $15,000 | 4 |

| Predictive Maintenance Software | 25% | 40% | $20,000 | 6 |

| Variable Speed Drives | 15% | 25% | $12,000 | 3 |

| Air Quality Monitoring Systems | 30% | 20% | $10,000 | 5 |

| Air Leak Detection Systems | 18% | 35% | $8,000 | 2 |

| Energy Recovery Systems | 22% | 15% | $18,000 | 7 |

| Integrated Control Systems | 27% | 50% | $25,000 | 8 |

| Heat Recovery Units | 19% | 30% | $11,000 | 4 |

| Automated Air Control Valves | 21% | 20% | $14,000 | 5 |

| Condition Monitoring Solutions | 23% | 45% | $16,000 | 6 |

Related Posts

-

The Ultimate Guide to Choosing the Right Compressed Air Dryer for Your Industrial Needs

-

Maximize Efficiency: The Surge in Industrial Air Compressor Rental Demand for Sustainable Practices in Manufacturing

-

Maximizing Efficiency: How Industrial Air Compressors Transform Manufacturing Processes

-

Maximizing Efficiency with Industrial Air Compressor Rental Services for Your Business Needs

-

Unlocking the Power of High Pressure Air Compressors for Home and Industry

-

The Future of Industrial Air Compressor Technology Innovations to Watch

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y