1-800-868-2450

My Account | Cart | Checkout

2026 Best Air Compressor Oil Reviews and Buying Guide?

When it comes to maintaining your air compressor, choosing the right air compressor oil is crucial. According to renowned expert John Smith, "The quality of air compressor oil can significantly impact the efficiency and lifespan of your equipment." This insight highlights the importance of selecting a suitable oil for optimal performance.

Air compressor oil serves as a lubricant, reducing friction and wear in the compressor’s components. A poor choice in oil may lead to increased breakdowns or decreased efficiency. Thus, understanding the different types of air compressor oil available can help you make an informed decision.

In the world of air compressor oil, not all products are created equal. There are synthetic options, mineral oils, and even biodegradable varieties. Each type has its advantages and drawbacks. Potential buyers need to consider factors like operating temperature and usage frequency. While many products claim to be the best, the reality might differ. It’s essential to research and read reviews before making a purchase. As users, we also need to reflect on our experiences and adapt to more effective choices.

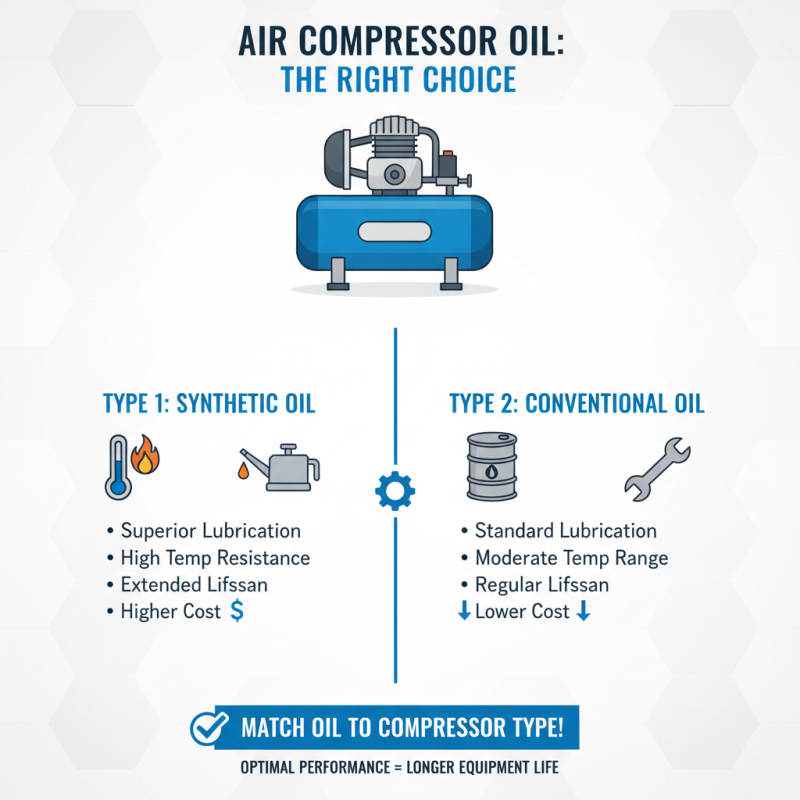

Types of Air Compressor Oils: A Comprehensive Overview

When choosing air compressor oils, it's crucial to understand the different types available. Mineral oil is the most common choice. It’s affordable and effective for light-duty tasks. However, it isn't as stable under high temperatures. This could lead to more frequent changes, so be cautious.

Synthetic oils are becoming popular for their high performance. They resist thermal breakdown and offer better lubrication. However, they come with a higher price tag. It's a trade-off between cost and efficiency. Users often feel unsure about which oil to choose.

Ultimately, semi-synthetic oils bridge the gap between the two. They provide some advantages of synthetic oils without the full cost. Many find it a suitable compromise. Yet, not everyone understands how to maintain these oils. Regular checks and changes are necessary for optimal performance. Ignoring this aspect can lead to premature wear and tear on your compressor.

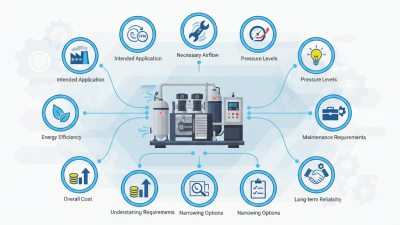

Factors to Consider When Choosing Air Compressor Oil

Choosing the right air compressor oil is crucial for optimal performance. It's essential to consider the oil type that matches your compressor. Synthetic oils often provide better lubrication and higher temperature resistance. They can prolong the lifespan of your machinery. However, they tend to be more expensive.

Viscosity is another key factor. The right viscosity ensures that the oil flows smoothly in different temperatures. Check your compressor’s user manual for specific requirements. Not paying attention to this can lead to premature wear. Additionally, mineral oils are cost-effective but might not perform as well in extreme conditions.

Additives in the oil also play a role. Some oils contain additives that reduce wear and prevent rust. These extra features can be worth the investment. However, not all oils boast the same quality, so researching is vital. Watching out for low-quality options may save you headaches later.

Top Brands of Air Compressor Oil Reviewed for 2026

When selecting air compressor oil for 2026, understanding top brands is crucial. The market shows that high-quality oil enhances performance. According to a recent industry report, proper lubrication can increase compressor life by up to 50%. This is significant for both hobbyists and professionals.

Key brands focus on synthetic and mineral oils. Synthetic oils offer better lubricating properties. They withstand extreme temperatures and reduce wear. However, they can be pricier. Mineral oils, while more affordable, may need more frequent changes. Reports suggest that 60% of users prefer synthetic oils for their longevity. This preference is driven by the need for efficiency and reliability.

Still, not all brands are equal. Some formulations may not perform well in certain environments. Users report that oil choice can affect the compressor's noise levels and operational efficiency. It’s essential to consider usage type. Higher demand applications may require specific oil formulas. Finding the right match can be challenging and may require trial and error.

How to Properly Maintain Your Air Compressor Oil

Maintaining your air compressor oil is crucial for extending the life of your equipment. Regular checks help prevent breakdowns. Ensure the oil level is adequate; too low can harm the motor. Change the oil as per the manufacturer's guidelines, but it may need to be more frequent in heavy use. Consider using an oil filter if your compressor doesn’t have one. This will keep dirt and debris out.

Tips: Always use the appropriate oil type for your compressor model. The wrong oil can lead to excessive wear. Monitor the oil's color and consistency. Dark or gritty oil signals contamination. Make sure to clean the compressor’s exterior to prevent dirt from entering the oil tank. Inspections should become a routine task.

Be mindful of specific conditions that may affect your compressor’s performance. Ambient temperature can influence oil viscosity. If the air is too cold, oil might thicken. Conversely, high temperatures may cause oil breakdown. Take these factors into account during maintenance routines. Regularly document the condition of your oil and compressor for better decision-making.

Common Misconceptions About Air Compressor Oil Usage

When it comes to air compressor oil, many users hold misconceptions. One common belief is that all oils are interchangeable. This is not true. Different compressors require specific oil types. Using the wrong oil can lead to increased wear and tear, ultimately shortening the machine's lifespan. A report by the National Institute of Standards and Technology (NIST) shows that using the wrong oil can increase operational costs by up to 15%.

Another misconception is that more oil means better performance. In reality, overfilling can cause foaming. This leads to poor lubrication and can damage internal components. The American Society for Testing and Materials (ASTM) recommends maintaining oil levels within specified limits to ensure optimal performance. Regular maintenance checks are critical. They can help identify oil quality issues before they escalate into bigger problems.

Many users think all synthetic oils outperform conventional ones. While synthetic oils often provide better temperature stability, they might not always be necessary. For many DIY compressors, the additional cost may not justify the benefit. Understanding your compressor's needs is key. Ultimately, informed choices about air compressor oil can prevent unnecessary repairs and improve efficiency.

Related Posts

-

Best Air Compressor Oil for Optimal Performance and Longevity?

-

2025 How to Choose the Best Air Compressor Oil for Optimal Performance

-

Top 10 Industrial Compressors of 2023: Performance, Efficiency, and Reliability Insights

-

10 Best Practices for Optimizing Your Compressed Air Piping System

-

How to Easily Find Affordable Compressor Repair Services in 2025

-

Top 10 Tips for Choosing the Best Industrial Compressor for Your Needs

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y